The World's Best and Only Eco Certified, Grease Recovery Unit

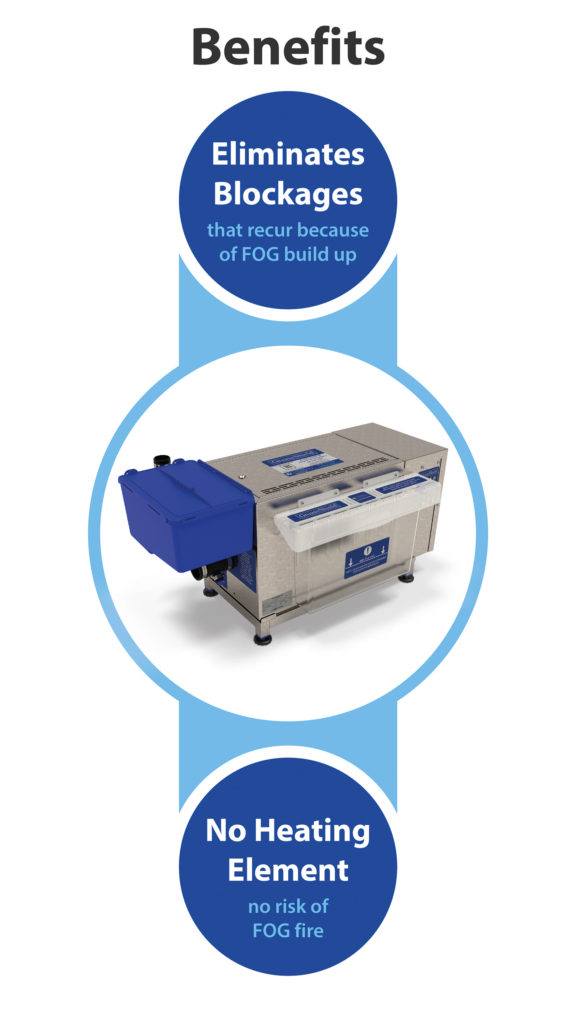

GreaseShield® separates and removes food solids and fats, oils and greases. GreaseShield® prevents blockages in drains and protects pumping stations whilst significantly reducing the loading on wastewater treatment plants. The recurring need to pump grease traps and refill with clean water is eliminated as is the use of biological agents, enzymes, and chemicals. Frequent pumping costs are eliminated.

How does the GreaseShield® work?

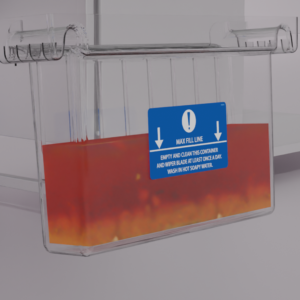

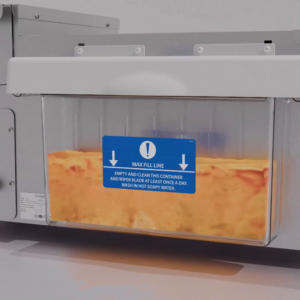

The GreaseShield® is a pro-active mechanical grease trap that operates in real time removing food waste and FOGs. It uses a patented design of cooperating baffles, including a magnetic baffle that encourages in-situ bioremediation without the need for additives, a reverse flow configuration, and recirculation of grey water plus recycling of waste thermal energy to remove FOGs before they solidify.

The GreaseShield® also removes and dewaters solid food waste by means of a PreFilter or FilterShield™ to prevent anaerobic foul-smelling conditions brought about by biological activity, depleting the dissolved oxygen present in the effluent. The GreaseShield® does not require any frequent pumping or chemical dosing, nor does it use a heating element like other automatic type units that are expensive to run and are a potential fire risk.